HISTORY AND FUTURE

Ties van den Nieuwenhuizen founded his company in 2013 and has successfully realized projects within the food and pharma industry using a combination of theoretical and practical knowledge. The vision is to continue solving complex challenges within any global supply chain. Below is a short (i.e. non-exhaustive) list of achieved results and competences combined.

Supply Chain project at Unilever N.V. (2016) – 4 months’ project

A global coordinated lean project for Unilever ‘Partner to Win’ program.

-

■provide guidance in scope alignment & cost breakdown

-

■ incorporating lean methodology

-

■value engineering & cognitive mapping

“… To prepare Unilever largest spend supplier in Flavour enhancers for Lean implementation …”

Procurement project at Unilever N.V. (2015) – 6 months’ project

A global sourcing project to negotiate and finalize raw material contracts.

-

■ identify and analyze target spend area Logo Unilever

-

■ develop a global strategy (director level)

-

■negotiate, evaluate, commit and agree spend exceeding €100M.

“… To write strategy on Unilever largest FE spend using an 8 step sourcing process methodology…”

Interim project at Unilever N.V. (2015) – 4 months’ project

A European sourcing project to negotiate and finalize raw material contracts

-

■ identify and analyze target spend area

-

■develop a global strategy (director level)

-

■ negotiate, evaluate, commit and agree spend exceeding €10M.

“… To substitute a European buyer on a complex vitamins portfolio…”

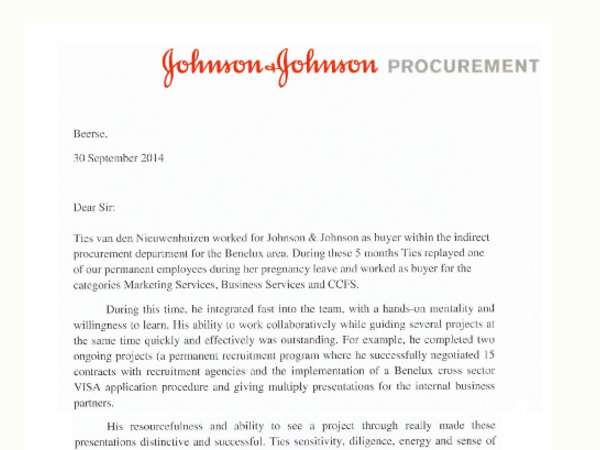

Interim project at Johnson & Johnson (2014) – 6 months’ project

A Benelux sourcing project to negotiate and finalize indirect material contracts

-

■ functional sourcing & cross-sector procurement in the Benelux Logo Johnson & John

-

■transactional procurement, driving compliance and spot buying

-

■ negotiate, evaluate, commit and agree spend exceeding €100K.

“… To substitute a Benelux buyer on an indirect procurement portfolio…”

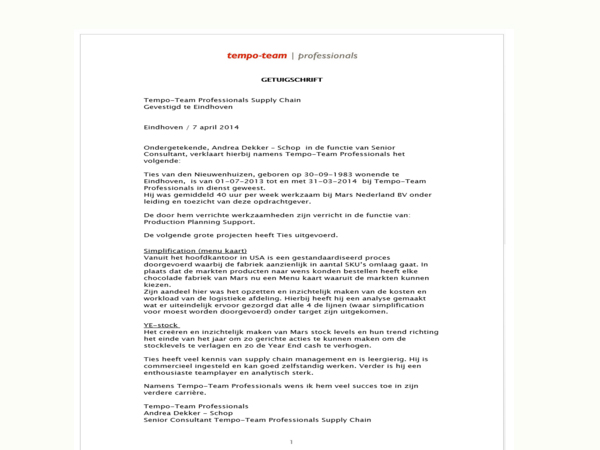

Supply chain project at Mars Inc. (2013) – 8 months’ project

An internal process improvement project with the main focus on simplification and YE-stock.

Project simplification:

-

■a HQ delegated project to reduce the total SKU’s produced.

-

■develop cost and workload breakdowns and provide insight

-

■implement a cost reduction of all four chocolate lines. Logo Mars

Project YE-stock:

-

■to create and providing insight into Year-end stock levels

-

■set out new goals based on the current trend

-

■reduce stock levels and thus increase the Year End Cash

“… To implement a cost reduction for the production planning…”

Supply chain project at Hödlmayr international (2009) – 5 months’ project

An internal and external improvement project on logistical processes.

-

■to make an analysis of current logistical situation Logo Hodlmayr

-

■ provide solutions (project Fast-Track)

-

■ implement project throughout the compound.

“… To implement a cost reduction for the logistical department…”

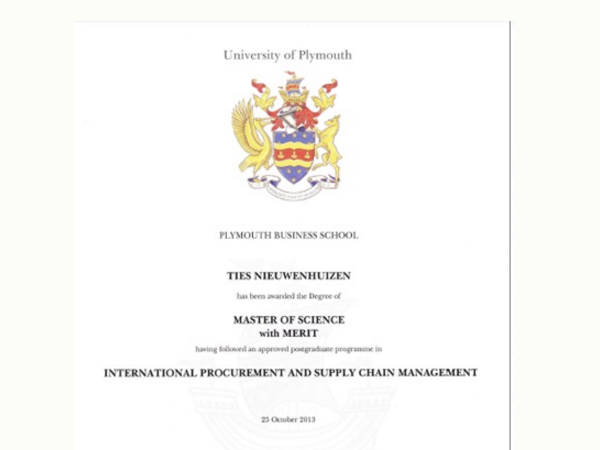

Documents

Relevant degrees, Certificates & reference letters

CONTACT

Please fill in the fields below to get in contact: